Introduction:

In the world of construction and engineering, precision is paramount. When it comes to the installation of Mechanical, Electrical, and Plumbing (MEP) systems, having a well-thought-out plan is essential. That’s where MEP shop drawings come into play. In this blog post, we’ll explore what MEP shop drawings are, why they are crucial, and how they can streamline the construction process for any project.

Understand MEP Services

The Role of MEP Systems: It effectively highlights the significance of MEP (Mechanical, Electrical, and Plumbing) systems in a building, emphasizing their crucial role in climate control, lighting, water supply, and overall functionality. The mention of accurate installation being essential for a building’s functionality and safety adds a valuable insight.

MEP Shop Drawings and Importance

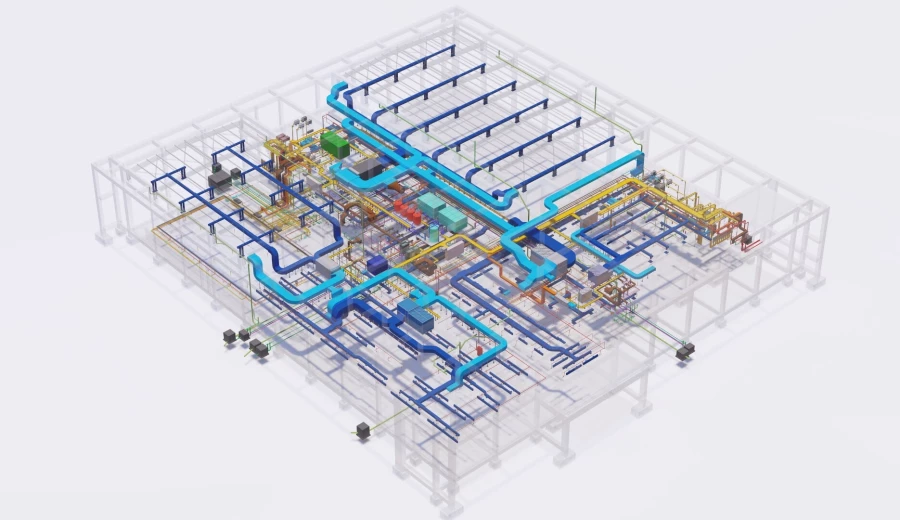

MEP shop drawings are detailed blueprints that illustrate how Mechanical, Electrical, and Plumbing (MEP) systems will be installed in a building. These plans encompass layouts, dimensions, materials, and other critical details, offering a comprehensive guide for construction and installation.

Importance

-

1. Precision and Coordination: MEP shop drawings ensure precise placement and seamless coordination of every component in MEP systems, eliminating guesswork during construction.

- 2. Cost Control: MEP shop drawings not only make sure things are in the right place but also help save money during construction by avoiding mistakes and rework.

- 3. Enhanced Efficiency: With clear and detailed plans, construction teams work more efficiently, minimizing the likelihood of errors and rework.

-

4. Interdisciplinary Collaboration: Facilitating coordination among trades involved in construction, MEP shop drawings ensure seamless collaboration between architects, engineers, and contractors.

-

5. Regulatory Compliance: MEP shop drawings serve as documentation, ensuring compliance with local building codes and regulations, validating proper system design and installation.

-

6. Getting Things Right: MEP shop drawings make sure all the parts of MEP systems are put in the right place, avoiding confusion during construction.

- 7. Working Smarter: With clear plans, construction teams can work better and make fewer mistakes.

- 8. Teamwork: MEP shop drawings help different construction teams, like architects and contractors, to work together smoothly.

- 9. Following the Rules: These drawings ensure that the building follows the local rules and codes, proving that the systems are designed and installed correctly.

Unveiling the Process of Creating MEP Shop Drawings

1. Initial Design The process begins with a detailed analysis of architectural and engineering plans. Designers use this information to plan the placement of MEP systems. 2. Drafting and Detailing Experienced drafters use Computer-Aided Design (CAD) software to create detailed drawings that specify the location of ductwork, wiring, pipes, and other components. 3. Coordination MEP shop drawings are often coordinated with other building plans to avoid conflicts. For example, the location of electrical wiring may need to accommodate the placement of structural beams. 4. Review and Approval The final shop drawings are reviewed by all stakeholders, including architects and engineers, to ensure accuracy and compliance. Once approved, they become the blueprint for construction.

Conclusion

MEP shop drawings are the unsung heroes of the construction world, ensuring that the intricate systems within a building work harmoniously and efficiently. They not only save time and resources during construction but also contribute to the long-term functionality and sustainability of a structure. Whether you’re embarking on a small renovation or a large-scale construction project, investing in MEP shop drawings is a wise decision that pays dividends in precision and efficiency